Lantor Soric vs. Lantor Coremat:

Lantor Soric vs. Lantor Coremat: Which Composite Core Material Is Best For Your Project?

Lantor Soric vs. Lantor Coremat: Which Composite Core Material Is Best For Your Project?

When choosing the right composite core material for your projects, it’s essential to understand the differences between Lantor Soric and Lantor Coremat. Both are renowned for their unique properties, designed to enhance performance, durability, and overall quality of composite structures. This blog will provide a comprehensive comparison to help you decide which material best suits your application.

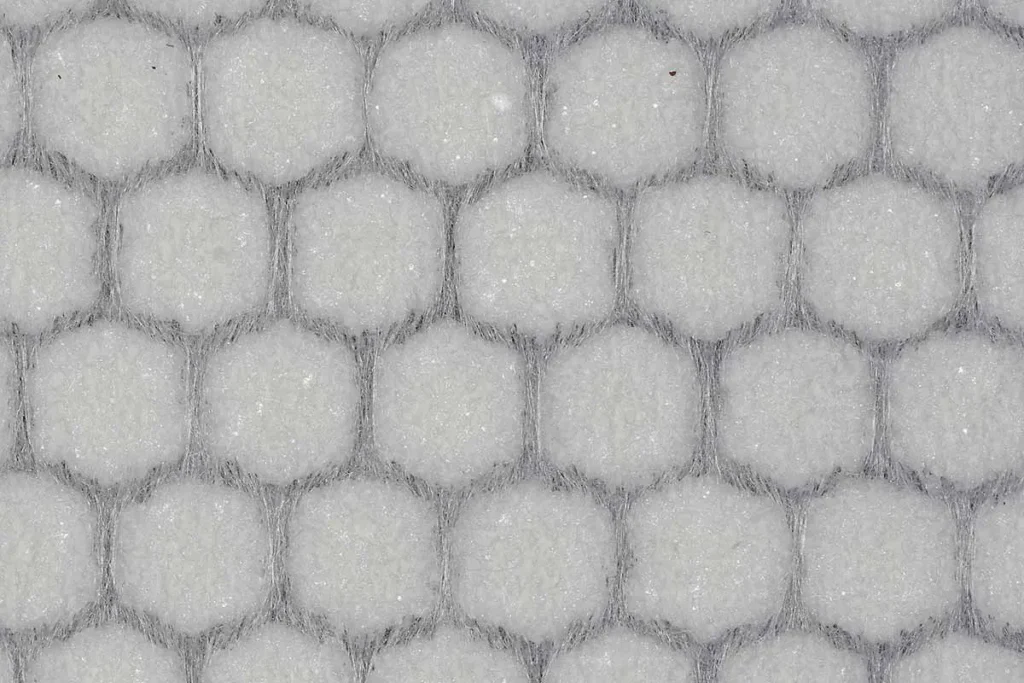

Overview of Lantor Soric

Lantor Soric is a popular core material in the composite industry, known for its resin flow capabilities, stiffness, and compression resistance. It’s a versatile solution used in applications where strength and lightweight properties are crucial.

Key Features

- Excellent resin flow management for infusion processes.

- Available in various thicknesses (1.5mm to 6mm).

- Provides superior compression resistance.

- Ideal for creating lightweight yet durable structures.

- Commonly used in marine, automotive, and industrial applications.

POPULAR PRODUCTS

Lantor Soric XF (6mm, 25m² per roll) – High stiffness and durability

Lantor Soric LRC (1.5mm, 70m² per roll) – Lightweight option for smooth surfaces.

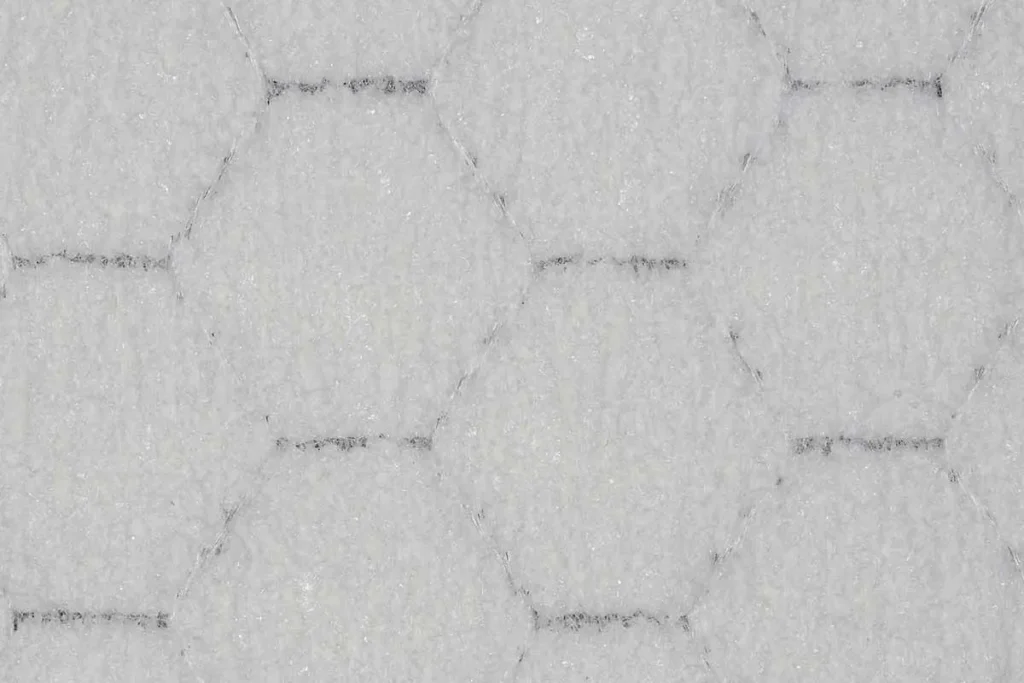

Overview of lantor coremat

Lantor Coremat is another high-quality core material designed to enhance the performance of composite structures. It is widely known for its thickness control, consistency, and durability in various applications.

Key Features:

- Exceptional thickness control, making it ideal for projects requiring precision.

- Designed for infusion and hand lay-up processes.

- Available in various thicknesses (2mm to 10mm)

- Highly durable and flexible for enhanced structural integrity.

- Commonly used in marine, construction and industrial sectors.

POPULAR PRODUCTS

Lantor Coremat XM (2mm, 80m² per roll) – Consistent thickness and easy to use.

Lantor Coremat XM (10mm, 15m roll) – Suitable for applications requiring significant thickness

Comparing Lantor Soric and Lantor Coremat

|

Feature

|

Lantor Soric

|

Lantor Coremat

|

|---|---|---|

|

Resin Flow Management

|

Excellent for infusion processes

|

Suitable for infusion & hand lay-up

|

|

Compression Resistance

|

High

|

Moderate

|

|

Weight

|

Lightweight

|

Slightly heavier than Soric

|

|

Available thickness

|

1.5mm to 6mm

|

2mm to 10mm

|

|

Applications

|

Marine, Automotive, Industrial

|

Marine, Construction, Industrial

|

|

Stiffness

|

High

|

Moderate

|

|

Durability

|

High

|

High

|

|

Cost

|

Moderate to High

|

Moderate

|

Which One Should You Choose?

Choosing between Lantor Soric and Lantor Coremat depends on your application’s specific needs. Consider the following factors:

- For Lightweight Structures: If weight reduction is a priority, Lantor Soric offers better compression resistance and stiffness.

- For Precision and Thickness Control: Lantor Coremat excels at providing consistent thickness, making it ideal for projects where precision is key.

- For Resin Flow Optimization: If your project involves infusion processes, Lantor Soric is an excellent choice for optimizing resin flow.

- For Durability: Both materials provide excellent durability, but Lantor Soric offers superior stiffness, making it more suitable for demanding structural applications.

Both Lantor Soric and Lantor Coremat offer exceptional benefits for various applications. Whether you need superior resin flow control with Lantor Soric or precise thickness control with Lantor Coremat, you can be sure that these products will enhance the performance and durability of your composite structures.

Explore our range of Lantor products today and find the perfect material for your specific needs.

Sources:

Lantor Coremat® XM images and Lantor Soric® XF & LRC images : Lantor Composites